CARE®:

Computer‑Aided Reliability Engineering Suite for RAMS

Build right from the start

Unified FME(C)A, FTA, RBD, allocation & testability for electronic systems

CARE® is BQR’s system‑level RAMS platform. It unifies FME(C)A, Fault Tree Analysis (FTA), Reliability Block Diagram (RBD), reliability allocation, Monte Carlo, and Testability Analysis into a single, traceable environment. Import assemblies, parts, and failure data from Synthelyzer® / fiXtress® or Excel / CSV; define environments, distributions, and repair policies; then compute reliability, availability, and safety KPIs with auditable models and reports.

CARE® is On-Prem (not cloud).

Watch a short CARE® intro about how to achieve unparalleled accuracy in your electronic RAMS analysis

Key Modules

FMEA / FMECA / RPN

Identify critical failure modes with customizable risk matrices; supports MIL‑STD‑882E, MIL-STD 1629a, SAE J1739, IEC 60812.

-

Sub Module:

Testability Analysis (TA) - Evaluate detection / diagnostics coverage to improve maintenance and system safety.

Mean Time to Repair (MTTR)

Define assembly failure modes and repair policies; remove and replace time. MIL-HDBK-472 compliance. Calculate MTTR and Mct.

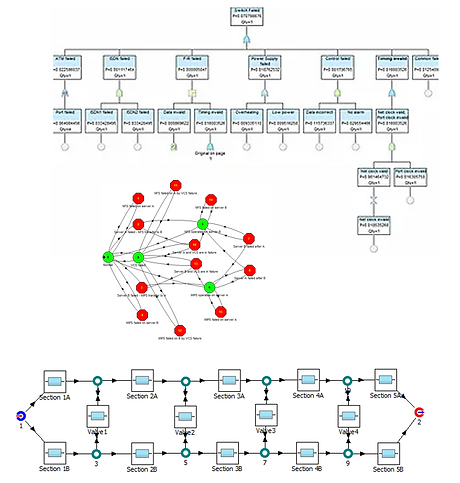

Fault Tree Analysis (FTA)

Analyze complex scenarios, perform cut‑set calculations; IEC 61025 compliant; integrates with FMECA for model seeding.

Supports nested common causes.

Reliability Block Diagram (RBD) & MTBF Allocation

Top‑down reliability/availability allocation and calculation; IEC 61078 / IEC 61165 / IEC 61508 compliant; multiple distributions (Exponential, Weibull, Normal, Log‑Normal).

Account for periodic preventive maintenance.

-

Sub Module:

Monte Carlo - Define duty cycles, repair policies; simulate system behavior to estimate KPIs (Reliability, Availability, MTBCF, MTTCF, MTTR).

Key Features

FMEA / FMECA

Flexible risk matrix and templates supporting industry standards.

ECAD Integration

Seamless integration with ECADs and fiXtress® for full traceability.

Testability / Diagnostics

Testability Analysis / Diagnostics Coverage including fault detection and false alarm metrics.

Reliability Block Diagram

Calculate reliability, availability, MTTR, MTBF and MTBCF of complex systems. Including networks and Markov chains.

Fault Tree Analysis

FTA for safety related calculation of event probability or safety function unavailability including cut-sets and common causes.

Reports

Detailed and Pareto reports for easy identification of safety issues and compliance reviews.

Advanced Analysis & Modeling

Mission Reliability

RBD calculates mission reliability accounting for redundancies, periodic maintenance and repair policies.

Fault Isolation

Identify fault signatures and calculate the possibility to isolate the fault to LRU / SRU level.

Common Causes

Account for common causes and nested common causes in fault tree models for safety analysis of systems with high inter-dependability.

Models

Fault Tree:

Used for analysis of safety event probability and key contributors.

Markov model:

Used for reliability / availability analysis of complex cases where items affect each other, e.g. load sharing.

RBD Network:

Calculate availability / Reliability of complex topologies e.g. telecom network.

Core Benefits

Unmatched accuracy

Analysis linked to latest board / product design; instant updates when designs change.

Streamlined V&V

MTBF, life expectancy, and critical component identification at a glance.

Seamless ECAD integration

Accelerate reviews and safety analyses by integration with ECAD Synthelyzer.

Efficiency at scale

Faster RAMS workflows than generic spreadsheets; consistent templates and reports.

Dependable insights

Gain insights from FMECA & Testability Analysis regarding Built In Test efficiency, preventive maintenance and fault isolation.

Superior design quality

proactively remove single points of failure and optimize redundancy and repair policies.

HOW It Works

Unified Data Import

Ingest product tree, components and failure modes by importing from BQR’s fiXtress® into the core CARE database.

Model & Analyze

Validate data quality; build RBD, FTA and FME(C)A models; set distributions and repair strategies; run allocations and Monte Carlo.

Iterate & Optimize

Test What‑Ifs on architectures, redundancies, mission profiles and maintenance concepts to hit targets and budgets.

Design feedback & traceability

Publish prioritized risks, cut‑sets, weak blocks and recommended mitigations; maintain full revision traceability to design baselines.

Integration with BQR's Toolchain

CARE® operates as part of BQR’s integrated

RAMS reliability ecosystem:

Extracts schematic/BOM and product structures directly from ECAD.

Provides electrical/thermal stress and realistic MTBF per part to seed CARE models.

Precise circuit simulation

Together, these tools provide a digital‑twin reliability workflow from schematic to system safety and reliability.

Standards & Compliance

-

FMEA/FMECA: MIL‑STD‑882E, SAE J1739, IEC 60812. MIL-STD-1629A

-

FTA: IEC 61025

-

RBD & Allocation: IEC 61078, IEC 61165, IEC 61508

-

Risk matrices and templates adaptable to sector‑specific practices

Outputs & KPIs

-

Reliability & Availability metrics by block and system (including Availability, MTBF, MTBCF, MTTCF, MTTR).

-

Critical items lists, minimal cut‑sets, weakest links and single‑point‑of‑failure reports.

-

Risk matrices and risk priority dashboards.

-

Exportable reports and data exchange with downstream safety and logistics processes.

Typical Use Cases

-

Safety‑critical systems (aerospace / defense, rail, medical, energy).

-

High‑availability assets (telecom, data centers, utilities).

-

Complex products with redundancy and maintenance constraints.

-

Design assurance for suppliers / OEMs and regulatory submissions.